News Story

UMD receives transformative battery manufacturing award

The U.S. Department of Energy (DOE) announced an investment of $25 million across 11 projects to advance materials, processes, machines, and equipment for domestic manufacturing of next-generation batteries. These projects will advance platform technologies upon which battery manufacturing capabilities can be built, enabling flexible, scalable, and highly controllable battery manufacturing processes. These innovations will advance the resilience and the success of domestic industrial manufacturing sector.

UMD will receive $2.6M for their work on Microfabricated Nanolayers for Solid-State Microbatteries. Microbatteries (MBs) have total volumes one-tenth of a cubic centimeter or less and they play an increasingly important role in our lives through the small devices they power; from life-extending medical implants to wearable consumer electronics, Internet of Things (IOT) devices, and more. This proposal directly addresses the need for US manufacturing of MBs, particularly in the context of national security and economic and technological competitiveness.

The work grew out of a collaboration between UMD and Forge Nano, a world-leading materials science company, during their joint work on the U.S. – Israel Binational Industrial Research and Development (BIRD) Foundation energy consortium. The U.S.-Israel energy consortium focuses on advancing the science and development of solid-state batteries, including work on advanced coatings, cell components, cells, and materials informatics software, for both Na and Li metal batteries. Additionally, the team at UMD has founded a start-up company Ionic Devices, which will be the vehicle for commercialization once the project is complete.

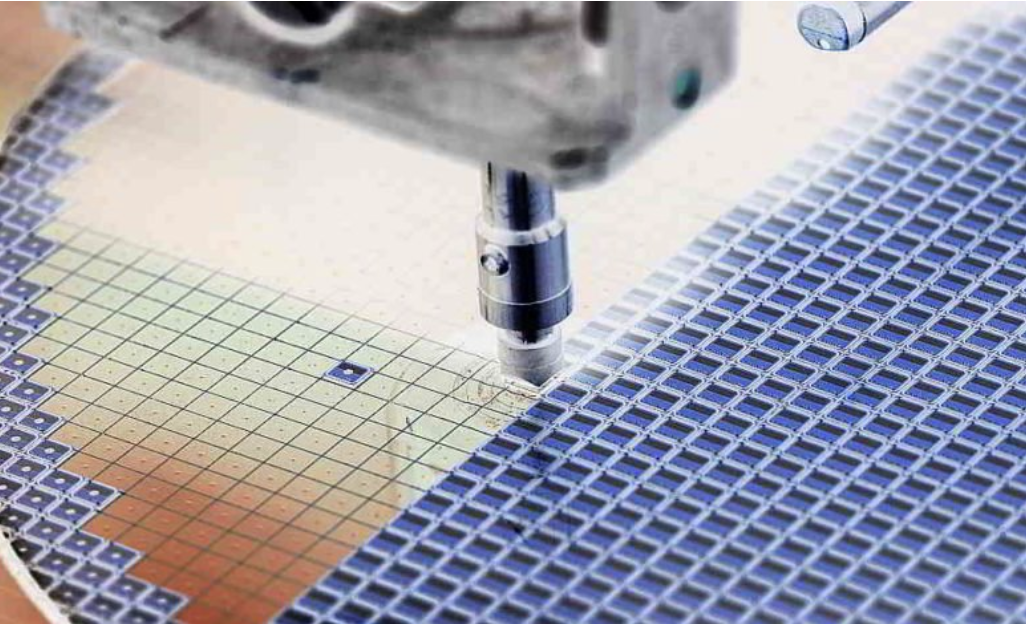

This new project will work towards a manufacturable, microfabrication-driven battery technology by transferring atomic layer deposition processes and materials from lab-scale research to manufacturing scale tools. These MBs are projected to have power and energy orders of magnitude higher than the state-of-the art MB’s and will additionally be significantly safer as the toxic and pyrophoric liquid electrolyte will be replaced with a safe solid-one. This solid-state design enables operation at extreme temperatures while ensuring complete safety. The team will work together to understand the science and economics to enable next-generation microfabricated 3D solid-state batteries and ionic capacitors to realize commercial applications.

Published January 8, 2025