Floods, heat waves, hurricanes, wildfires, and other natural and climate disasters—all occurring with more intensity, and at increasing frequency. For those coping with the impacts of a rapidly warming world, climate change is one expensive habit: Every state in the U.S. has been impacted by at least one billion-dollar disaster since 1980, and the costs of these disaster events are increasing over time.

Behind the largest source of greenhouse gas emissions is the energy sector, and especially the burning of fossil fuels for electricity, heat, and transportation. (The International Energy Agency estimates that energy accounts for more than three-quarters of total greenhouse gas emissions globally.) The impacts of climate change—extreme weather and natural disasters among them—cycle back to the energy sector, where they can threaten local and global energy supplies, systems, and infrastructure.

Engineering humanity away from the challenges of climate change demands a reset in how society thinks about, produces, and uses energy. At Maryland Engineering, researchers, faculty, and students are already rising to the grand challenge of researching, developing, and commercializing the clean energy technologies that meet society’s urgent needs for a sustainable future.

Setting the Stage: The Legislative Drivers

In 2022, Maryland passed the Climate Solutions Now Act (CSNA). The law mandates a 60 percent reduction in greenhouse gas emissions by 2031 and net-zero carbon by 2045, one of the most rigorous carbon reduction targets for any U.S. state.

The good news: In 2020, the state was already halfway to its 2031 goal, according to Maryland’s Climate Pathway Report.

The not-so-good news: The state still faces a significant gap between its goals and strategies. Maryland needs to account for 10.6 million metric tons of carbon dioxide before it can meet the targets spelled out in the CSNA—the equivalent of annual emissions from 2.35 million gas-powered cars.

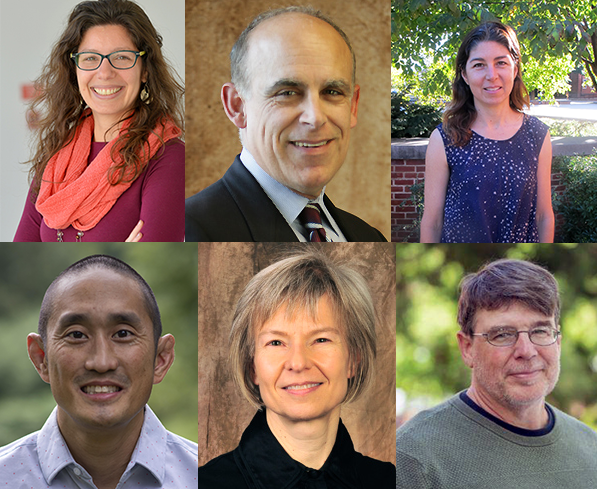

The final miles are going to be the roughest slog, experts predict. After all, expensive solutions like the electrification of commercial transportation, industrial processes, and building heat might be a harder sell, says Paul Albertus, associate director of UMD’s Maryland Energy Innovation Institute (MEI²). “To get to net zero by 2045 in a way that’s socially and fiscally responsible is not going to be easy,” he argues. “There are cost tradeoffs that have to be considered, and innovation is needed to ensure the costs are what people are willing to pay.”

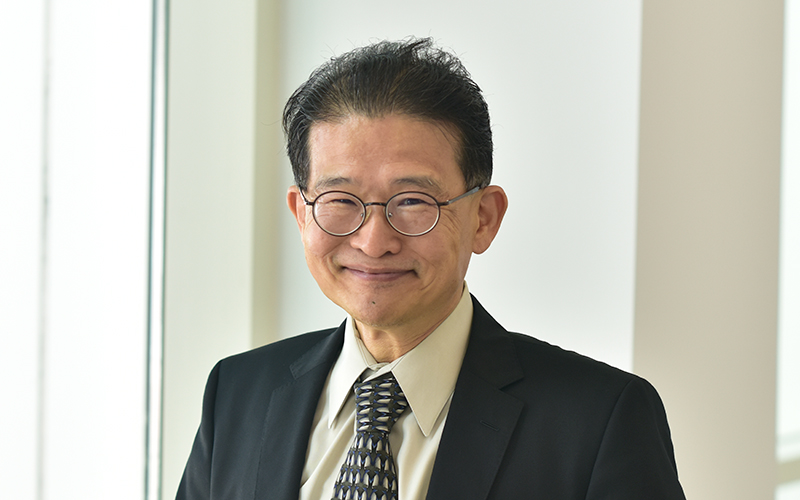

Nevertheless, “to turn ambitious net-zero goals into action, we need to bridge the gap between policy and implementation,” says Distinguished University Professor and MEI² Director Eric Wachsman. “We need engineered solutions that can be quickly commercialized and make a real difference in achieving decarbonization.”

This is where Maryland engineers are already answering the call: at the forefront of advancing an ecosystem of solutions needed by not just the state, but the world.

Making the Change: Engineered Solutions

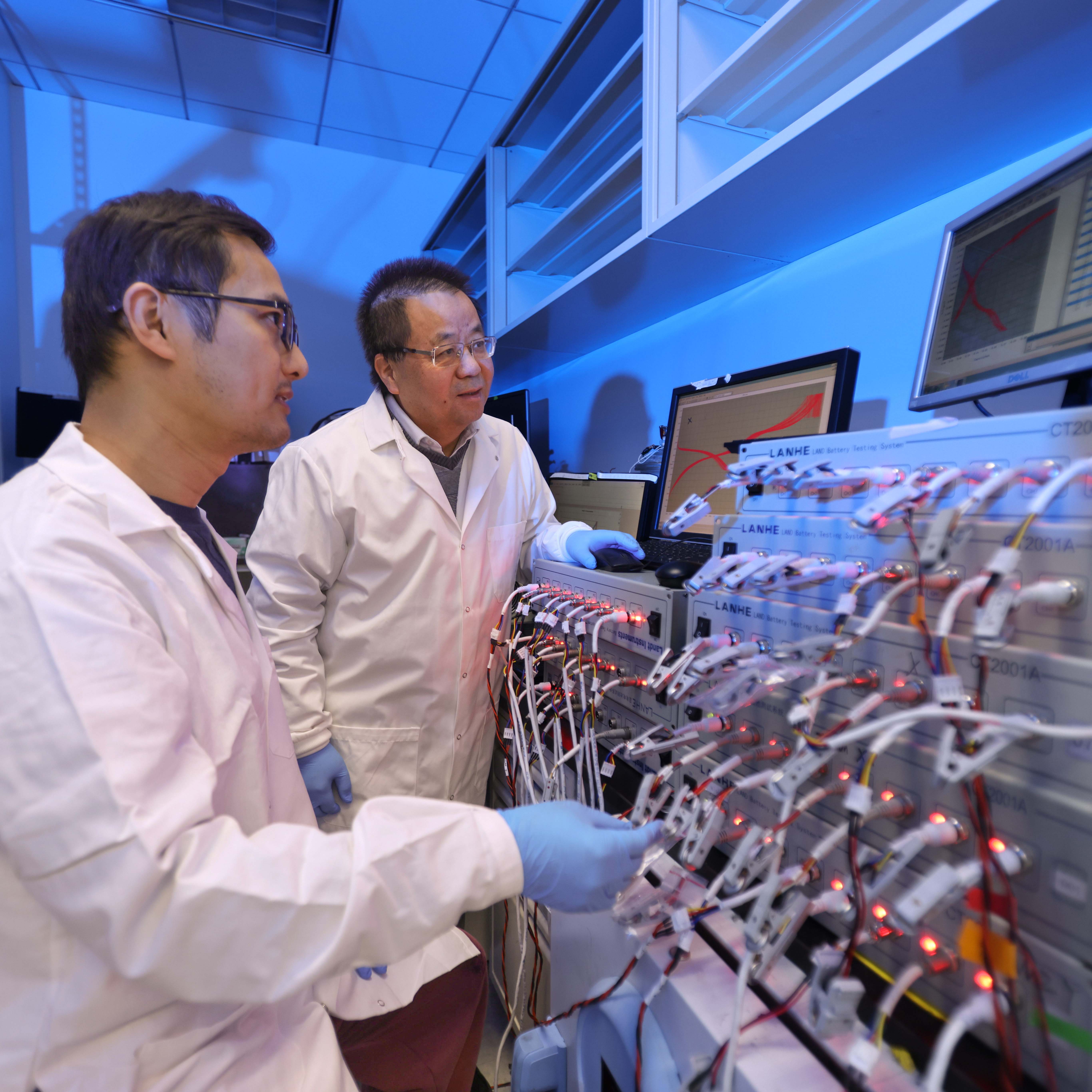

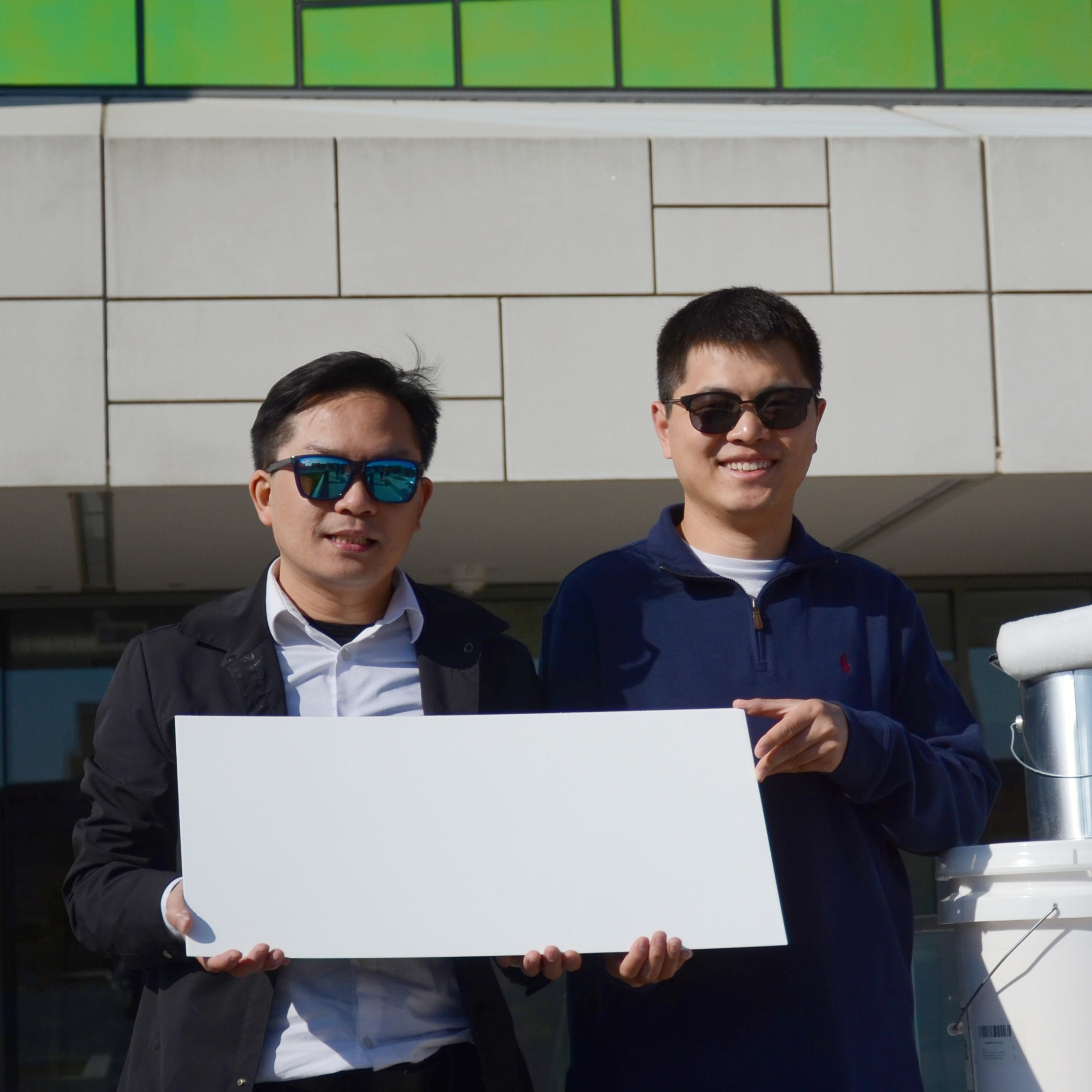

Christopher Tang and Michael Danner fabricate next generation solid-state batteries.

Christopher Tang and Michael Danner fabricate next generation solid-state batteries.

Solid-state batteries

Alternative renewable fuel sources such as wind and solar are transient: “You can’t control when the wind is blowing or when the sun will shine,” Wachsman points out. That’s why batteries, which can store and release solar and wind energy as needed and solve critical needs like electrifying transportation, are essential to achieving long-term decarbonization goals. The demand mirrors the situation on the ground: Strategic market research firm Research Nester projects the global battery energy storage market size will reach $212.8 billion by 2035. In November 2023, the U.S. Department of Energy (DOE) announced up to $3.5 billion from the Infrastructure Law to “boost domestic production of advanced batteries and battery materials nationwide.”

At Maryland, Wachsman and his team are building the solid-state batteries considered the future of energy storage. Wachsman’s innovative batteries offer significantly higher energy density than traditional lithium-ion counterparts, and are non-flammable in contrast to today’s lithium-ion batteries that employ flammable liquid electrolytes. Their new ceramic lithium-conducting materials and structures not only achieved the DOE fast-charge goal, but exceeded it by a factor of 10, theoretically enabling an electric vehicle to charge in 1.5 minutes.

Such solid-state batteries are viable replacements for lithium-ion batteries, the primary driver for electric vehicles (EVs). Given that Maryland aims to reduce greenhouse gas emissions by transitioning the state fleet to zero-emission vehicles or electric vehicles, research UMD engineers could play a prominent role in helping us get there.

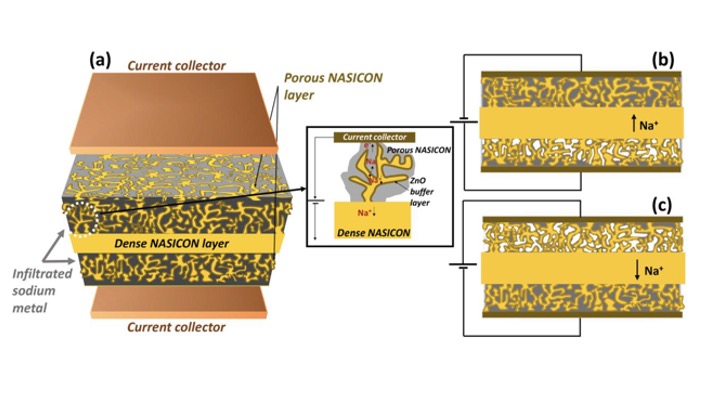

Wachsman’s team has also developed solid-state batteries with Sodium (Na) Super Ionic Conductor (NASICON) materials, which are nonflammable and deliver high conductivity achieving comparable current densities. Sodium is much more earth-abundant than lithium, providing a more sustainable and lower cost alternative that is particularly suited for the grid-scale storage necessary to harness wind and solar power generation.

“We need engineered solutions that can be quickly commercialized and make a real difference in achieving decarbonization.”

Eric Wachsman

Katrina Groth refueling a Toyota Mirai at a hydrogen filling station in California. Work in Groth’s lab is enabling the buildout of hydrogen infrastructure globally.

Hydrogen fueling stations

In the move away from fossil fuels, there’s a lot of hope pegged on hydrogen: COP28, the 2023 United Nations Climate Change Conference in Dubai, listed hydrogen as one of the key energy technologies for the future. And, the 2023 Bipartisan Infrastructure Law includes $8 billion in funding to deploy hydrogen hubs in the U.S.

At Maryland, Associate Professor Katrina Groth, who directs UMD’s reliability engineering program, is leading risk assessment studies to help establish codes and engineering standards for the safe development, permitting, and placement of hydrogen fueling stations and electrolyzers.

“I’m hoping to make a case to the state that the University of Maryland is the place to come for hydrogen safety studies. We have an entire ecosystem of research and engineering projects, and of course education, to really grow the expertise in this area that our state and our nation needs,” Groth says.

"[University of Maryland has] an entire ecosystem of research and engineering projects, and of course education, to really grow the expertise in this area that our state and our nation needs."

Katrina Groth

A Maryland Power Electronics Laboratory PV Micro-inverter.

Solar energy

A different kind of renewable energy drives Professor Alireza Khaligh: At Maryland, he and his team are developing power-efficient inverters that could flip the switch toward a wider embrace of solar. With a focus on power electronic interfaces for solar energy conversion systems, their work could lead to next-generation residential and commercial solar photovoltaic systems.

“We are trying to reduce the carbon footprint of these systems; we’re making these converters smaller, lighter, more efficient, and cheaper,” Khaligh says. “We are building converters with a goal of over 97 percent efficiency. That's how we are trying to address climate change,” he adds.

When the team meets cost targets, Khaligh’s inverters could also make solar more affordable to a wider demographic range.

“We are building converters with a goal of over 97 percent efficiency. That's how we are trying to address climate change.”

Alireza Khaligh

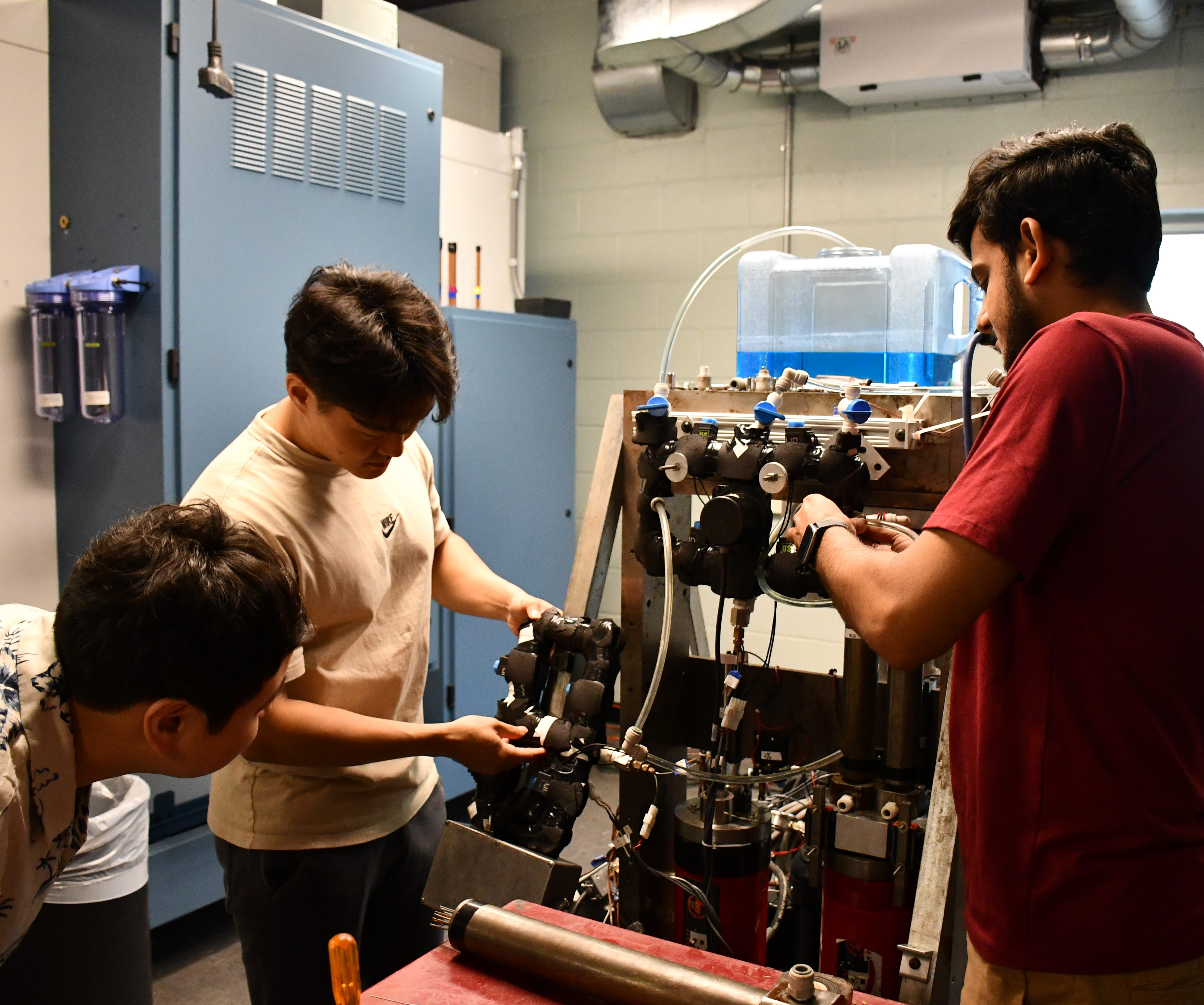

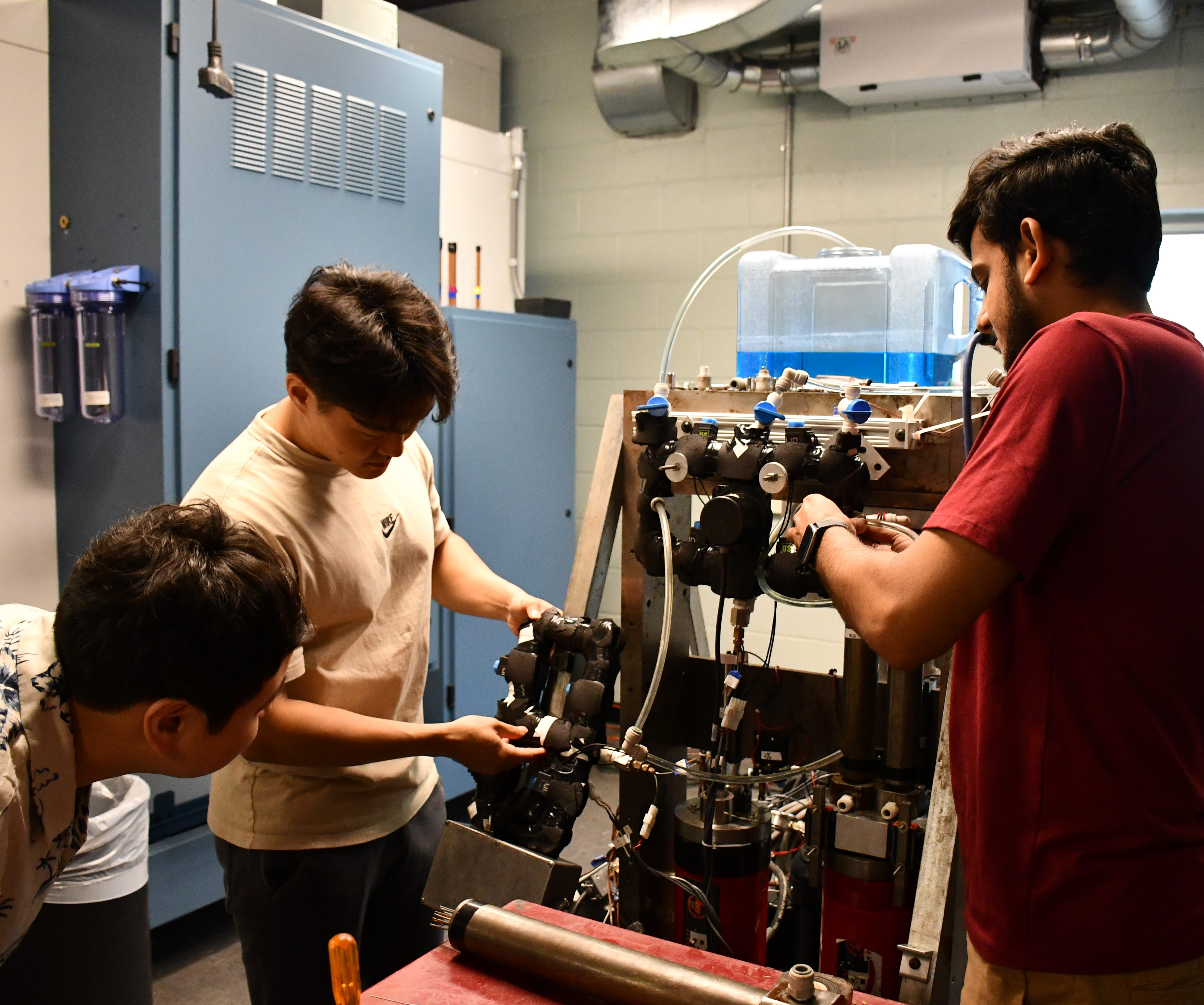

CEEE graduate research assistants (left to right), Manchul Jeong, Jangho Yang, and Het Mevada working on an elastocaloric cooling system prototype based on the shape memory alloys. It is a possible future cooling system that does not use environmentally harming refrigerants.

CEEE graduate research assistants (left to right), Manchul Jeong, Jangho Yang, and Het Mevada working on an elastocaloric cooling system prototype based on the shape memory alloys. It is a possible future cooling system that does not use environmentally harming refrigerants.

Building efficiency

By 2045, Maryland could see a doubling in demand for electricity. Under the stress of growing populations and a rapidly warming climate, air conditioners will need to work smarter—not harder—to reduce the heat-trapping carbon they produce while efficiently cooling our homes, schools, and businesses.

In fact, Maryland law mandates that most buildings of at least 35,000 square feet reduce their carbon footprint by 20 percent by 2030. Research Professor Yunho Hwang, who co-directs UMD’s Center for Environmental Energy Engineering, is undertaking research to break through the ceiling: his team’s work could improve energy efficiency of building HVAC systems by 300–400 percent (compared to conventional electric heating), using heat pump technology.

Being close to the federal government seat of power helps, Hwang says. “We are playing a leading role in the energy efficiency and decarbonization sectors,” he adds.

“We are playing a leading role in the energy efficiency and decarbonization sectors."

Yunho Hwang

Walking the Walk: The Commercialization Pathway

Hatching a great idea is only the first step. As Wachsman says, “It’s not enough to do great research [to address climate change]; we have to get products out into the market to have real impact.”

The Clark School’s ecosystem approach: Located on UMD’s College Park campus, MEI² supports the development of clean energy technology innovations from universities and companies across Maryland in conjunction with the university’s Maryland Technology Enterprise Institute (Mtech) and the state’s Maryland Clean Energy Center (MCEC). MEI²’s goal: harness the collective brainpower of area talent to reach climate goals by guiding researchers through a commercialization pathway that enables breakthroughs to go from bench (or laboratory) to boardroom.

MEI² in partnership with MCEC provides critical infrastructure and funding to guide academic researchers through the unfamiliar process of turning a paper into a prototype; demonstrating a new technology’s ability to go to market; building up business and manufacturing infrastructures; developing supply chains; and raising private capital.

Among MEI²’s methods to facilitate commercialization of promising energy-based research is its seed grant program, which finances early-stage startups to grow beyond proof-of-concept. Since its 2017 inception, MEI² has granted $2.6 million in funding to 22 companies and university researchers. A survey of these companies showed that they created 134 full-time jobs, filed 124 patents, obtained a total of $142 million in funding ($70 million in private investment and $76 million in federal/grant funding), and produced $4.5 million in revenue over the past six years.

Seeding Growth: Grant Recipient Spotlight

Ion Storage Systems (ION) is based on solid-state battery technology developed by Distinguished University Professor Eric Wachsman, who together with chief technology officer and UMD alum Greg Hitz ’09, Ph.D. ’16 founded the innovative battery company.

ION’s ceramic electrolyte in a 3D porous architecture delivers a lightweight, nonflammable, sustainable, and locally sourced alternative to current problematic contenders such as lithium-ion and lead-acid counterparts. Neil Ovadia, Vice President, Supply Chain, ION, shares his thoughts about the genesis for the company.

Read More

Leading the Charge: Building the Talent Pipeline

As part of Maryland’s CSNA, the Just Transition Working Group will begin meeting this year and is tasked with evaluating opportunities for workforce development and training related to energy efficient measures, renewable energy, and other clean energy technologies.

The demand for talent is not limited to Maryland alone. Engineered solutions like clean hydrogen will be instrumental in a number of “hard-to-decarbonize” sectors, including heavy-duty transportation, industrial and chemical processes, synthetic fuels, and long-duration energy storage. On a national scale, the DOE projects that by 2030, the U.S. will need 100,000 trained hydrogen professionals.

Maryland Engineering professors like Groth are gearing up by launching the multidisciplinary Hydrogen Training and Engineering Research Program for Safety (HyTERPS) program. The initiative will create a standardized program for training technicians on protocols for the safe installation and operation of hydrogen fueling stations.

For civic-minded students who want to use their engineering education to make positive change, UMD’s clean energy curriculum provides the necessary spark. Undergraduate classes range from “Engineering for Sustainability” and “Li-Ion Battery Design, Fabrication and Testing” to “Engineering for Social Change” and “Launching Technology Startup Ventures.” Programs through Maryland Applied Graduate Engineering meet the needs of working engineers and technical professionals, wherever they’re at (enrolled students can complete their coursework in-person at the UMD campus in College Park, or online from anywhere in the world). Outside of the classroom, opportunities for research, competition including the Terps Racing Formula EV Team, and real-world outreach such as Engineers Without Borders abound.

With the right solutions, a rock-solid commercialization infrastructure, and a talent pipeline nurtured to meet workforce needs, society is poised to take on one of our most challenging problems.

“We’re on the cusp of a massive and significant change in the energy industry,” Groth says. “We have the opportunity, as a society, to rethink our relationship with energy and to try new things. That opportunity comes along very few times—I’m more excited than ever about where the energy transition is going.”

“The world comes to Maryland Engineering for solutions to these and other intractable programs,” she adds. “As part of a world-class engineering school, it’s exciting to build solutions to actually address climate change.”

Drive Sustainability Forward

Picture a classic Formula One race car: you might envision a sleek, gas-fueled model hugging tight corners at blistering speeds. Yet, tinkering away in a campus workshop, Maryland Engineering students are reimagining an innovative alternative: a Formula-style experience for a sustainable future.

As part of the Terps Racing Formula EV Team, University of Maryland (UMD) students build a fully electric car with an eye towards SAE International’s annual Formula SAE Electric competition (the 2024 event will be held June 12–15 in Brooklyn, Michigan).

The car runs on a custom battery pack and three-phase electric motor—one that can take the dauntingly tight turns of a race track at speeds greater than 100 km/hour (about 62 miles/hour). The annual endeavor coaches future generations of green engineers—and is one small, but vital way the university is fueling the pipeline for talent as the state of Maryland realizes its ambitious goals to address carbon emission reduction, energy efficiency, and the electrification of transportation.

Story by Poornima Apte; illustrations by Chris Gash

Christopher Tang and Michael Danner fabricate next generation solid-state batteries.

Christopher Tang and Michael Danner fabricate next generation solid-state batteries.

CEEE graduate research assistants (left to right), Manchul Jeong, Jangho Yang, and Het Mevada working on an elastocaloric cooling system prototype based on the shape memory alloys. It is a possible future cooling system that does not use environmentally harming refrigerants.

CEEE graduate research assistants (left to right), Manchul Jeong, Jangho Yang, and Het Mevada working on an elastocaloric cooling system prototype based on the shape memory alloys. It is a possible future cooling system that does not use environmentally harming refrigerants.