News Story

UMD-Harvard team wins ARPA-E award for Transformational Energy Technology

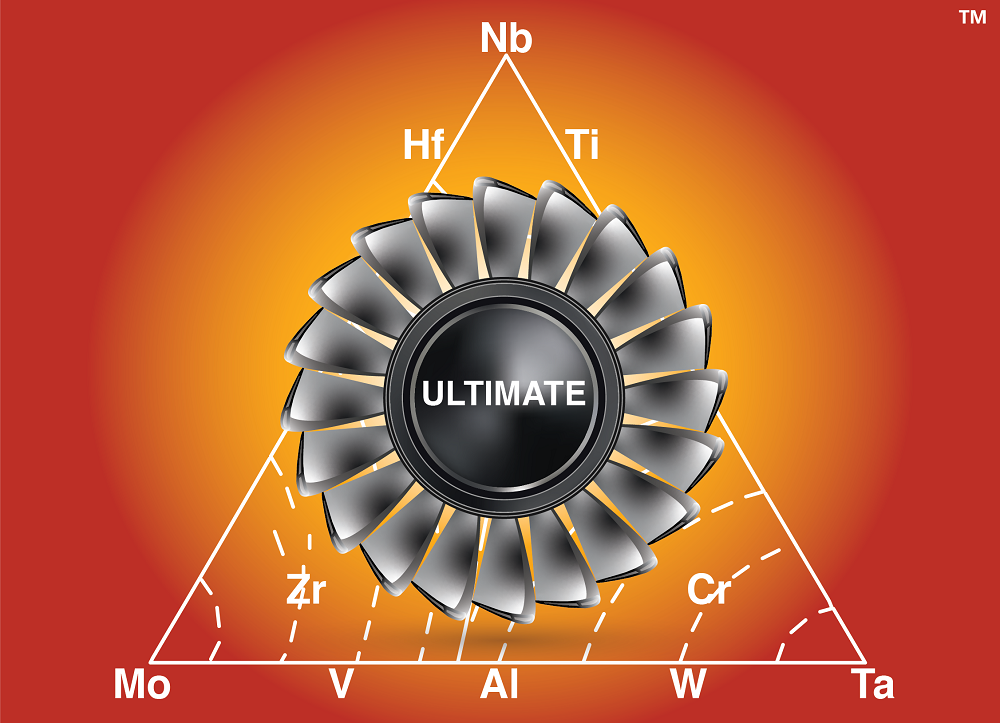

A joint team from the University of Maryland (UMD) and Harvard University is among the 17 teams selected by the US Department of Energy to develop ultrahigh temperature alloys and coatings as part of the ULtrahigh Temperature Impervious Materials Advancing Turbine Efficiency (ULTIMATE) Program of the Advanced Research Projects Agency-Energy (ARPA-E). ULTIMATE teams will develop ultrahigh temperature materials for gas turbine use in the aviation and power generation industries.

“Natural gas turbines generate more than a third of the country’s electricity, supplying power to consumers across America,” said ARPA-E Director Lane Genatowski. “ULTIMATE teams will improve the efficiency of the generation sector by developing materials that increase producers’ efficiency and create positive economic benefits for industrial and public consumers nationwide.”

“We are thrilled to be part of the ARPA-E ULTIMATE Program to develop 1700 °C (about 3,100 °F) capable environmental and thermal barrier coatings (ETBCs) for next generation jet engines and electricity-generation gas turbines,” said JC Zhao, UMD Materials Science Engineering (MSE) Department Chair, who leads the UMD-Harvard team; “Our team has excellent experience and unique approaches to develop ETBCs to enable much higher efficiency of both jet engines and gas turbines”.

For Zhao, this project returns to his roots of developing high-temperature alloys and coatings. Before academia, Dr. Zhao worked at GE Research Center for 12 years and was a co-inventor on 48 issued US patents, most of which are on new alloys and coatings. A superalloy he co-invented is now widely used in GE electricity-generation gas turbines.

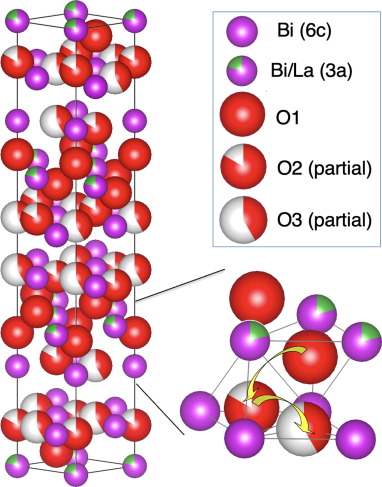

The new project is entitled “New Environmental-Thermal Barrier Coatings for Ultrahigh Temperature Alloys”. The team will leverage a unique, high-throughput materials synthesis approach invented by UMD MSE Professor Liangbing Hu, who is the Director of a newly formed Center for Materials Innovation and who serves as a Co-Principal Investigator (PI) of the project. Hu’s group recently invented an ultrafast high-temperature sintering (UHS) method that was featured on the front cover of the May 1 issue of Science. UHS enables high-temperature ceramic coatings to be made in less than a minute at high temperatures. Additional Co-PIs include Harvard University Professor David R. Clarke, a renowned expert with more than 30 years of experience on high temperature ceramics and coatings, and Dr. Chengwei Wang who co-invented the UHS process and is the CEO of UMD spinoff High-T Tech LLC.

“We have a great team and great approaches,” said Zhao, “We are very confident that we will invent new coatings to meet the demands of ultrahigh temperature engines and turbines envisioned by ARPA-E.”

“I am very excited for this new ARPA-E project with a focus on developing new high temperature coatings using the UHS method,” said Hu.

The coating technology together with ultrahigh-temperature alloys to be developed under the ULTIMATE Program may lead to substantial reduction of green-house gas emissions from the aviation and power-generation sectors.

This project marks the 28th ARPA-E award received at UMD for a grand total of $64M.

Published December 9, 2020