News Story

A Greener Alternative to Hot-Mix Asphalt

Green technologies help protect the environment, but are they a boon to business? In the past, many companies and organizations balked at the cost. But not all planet-friendly practices dent the bottom line; indeed, some can save costs and yield added revenue.

An example, says UMD civil and environmental engineering professor Qingbin Cui, is the use of recycled highway materials to build or replace pavement.

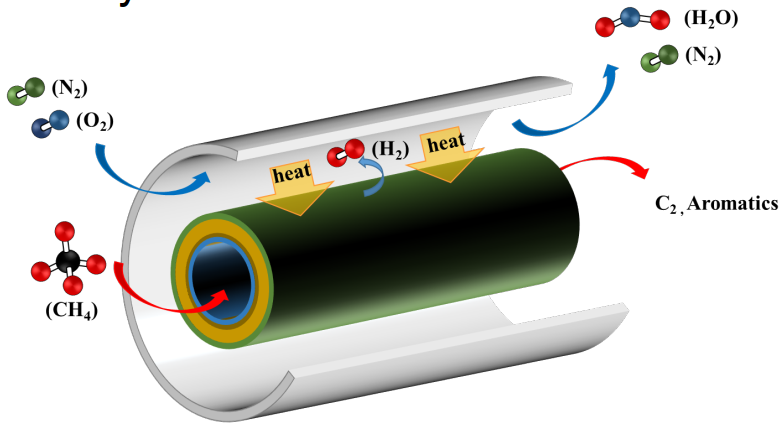

Manufacturing hot-mix asphalt—the traditional method that contractors have relied on since the dawn of the automobile era—is a messy, complex procedure. Not only does it create pollution, but the mix must be transported from the plant to the worksite, thus releasing more carbon dioxide into the atmosphere and racking up fuel costs.

Recycled pavement, by contrast, is manufactured on site through a non-thermal process that uses foamed asphalt—a mix of air, water, and bitumen—to bind together the reclaimed material.

It’s not only cheaper than hot-mix asphalt, but generates less emissions. The lowered emissions earn credits that can then be traded on the carbon emissions market.

“It’s one way to move green technology from the ‘cost’ to the ‘revenue’ side of the balance sheet,” Cui says.

Cui and colleagues at UMD’s A. James Clark School of Engineering have collaborated with a Maryland-based business leader, Harold Green, to develop a framework for quantifying the emissions reductions. Their work—building on earlier research conducted by UMD civil and environmental engineering department chair Charles W. Schwartz (MIT Course I BS, MS, PhD)—has borne fruit: earlier this year, the framework was officially accepted by Verified Carbon Standard (VCS), the world’s largest greenhouse gas reduction program.

VCS has certified almost 1,500 projects to date, leading to the reduction or removal of more than 200 million tons of carbon and other emissions from the atmosphere.

Green, who runs multiple companies—including Chamberlain Contractors and GRR Engineering --believes it will win widespread acceptance as more and more organizations see the benefits. “It’s environmentally friendly and a lower cost material, and it’s equal to many conventional hot-mix asphalts,” he says.

Not that it will happen overnight. “Changing the way we engineer our parking lots and road systems takes time,” Green acknowledges. “People have to change their mindsets and look beyond the methods they’re used to, and that can be a lengthy process. But in 20 or 30 years, I believe, this will be the standard.”

Cui, meanwhile, sees harnessing market forces as a way to change mindsets and behavior, to a degree that is hard to accomplish through regulation alone.

“Environmentally friendly practices are often seen as expensive. You have to pay fees to obtain green certification, and you’re adopting different methods and materials that cost more than what you’re used to paying. Use of recycled materials is different. It’s an example of a technology that not only helps the environment, but can provide savings and even be a source of revenue,” he notes.

“That’s important, because most organizations are worried about the cost factor,” Cui says. “When there’s a significant economic incentive, then we can expect to see changes start to take place.”

Published September 5, 2019