News Story

Computer Algorithms Help Improve Emissions Control

Originally invented with the aim of reducing pollution from factory smokestacks, the catalytic converter is now an essential component of gas-powered vehicles: without one, a car stands no chance of passing an emissions test. The technology depends on materials that, in other contexts, might make for a pricey gift.

“We often associate platinum with jewelry, but the reality is that 50% of the platinum we use is found in catalytic converters,” explains Keystone Professor of Engineering Teng Li. Together with UMD researchers Tian Guo and Lianping Wu, Li has been helping to pioneer a new approach that could significantly bring down costs—and perhaps allow more platinum to be used for fashion rather than emissions control. A paper detailing their work has been published by the Journal of Materials Chemistry A, published by the Royal Society of Chemistry, and also featured as the back cover of Issue 37 of the journal.

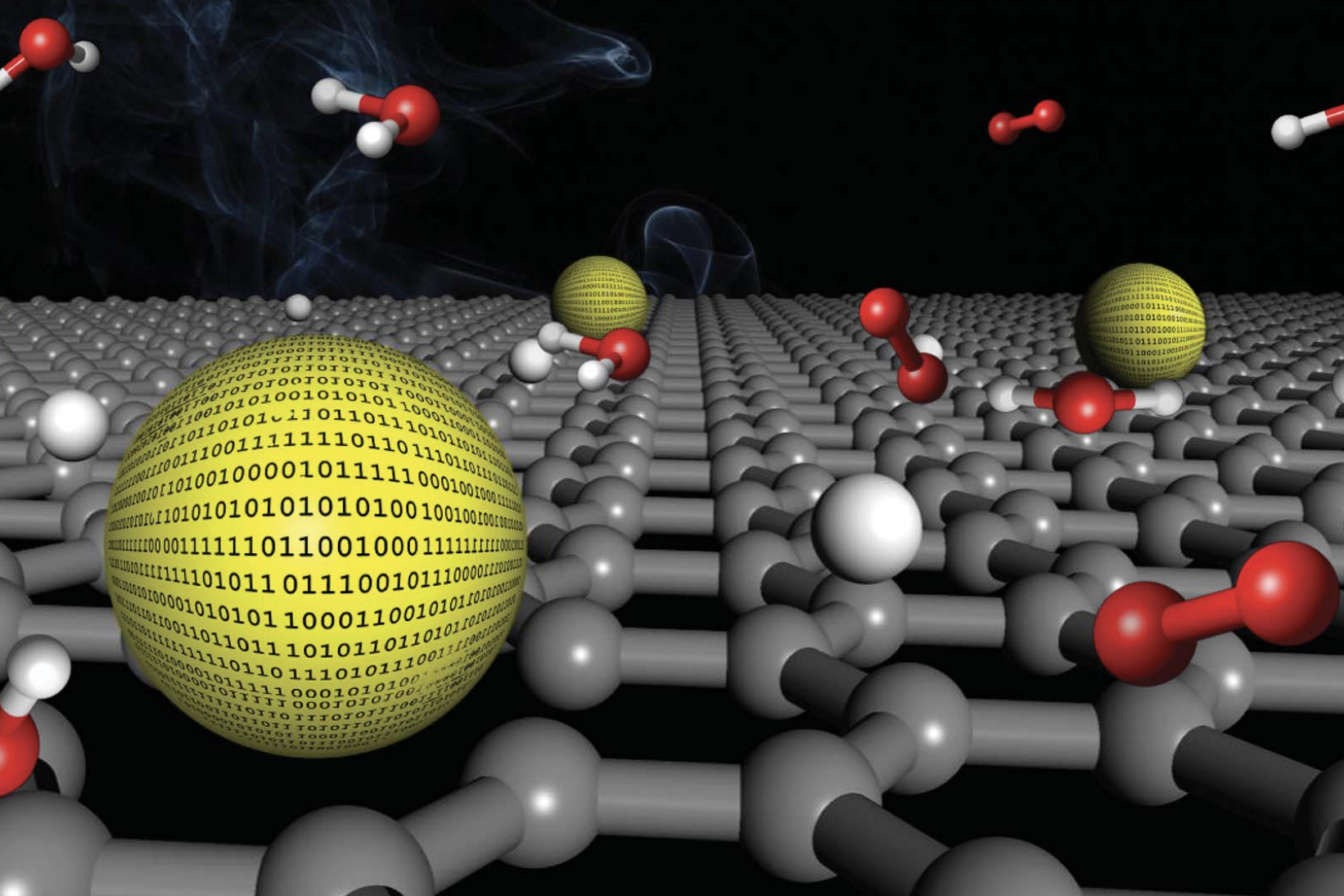

The holy grail, for catalytic converter technology, is the use of so-called “single atom catalysts” (SAC). These maximize efficiency because every individual atom in the system contributes to the catalyzing process. In a conventional system, by contrast, some atoms are hidden below the material surface and remain passive. But SACs have to be tested and their performance measured, and until now that has proved a barrier: the process is far too computationally intensive and time consuming to be cost-effective.

The holy grail, for catalytic converter technology, is the use of so-called “single atom catalysts” (SAC). These maximize efficiency because every individual atom in the system contributes to the catalyzing process. In a conventional system, by contrast, some atoms are hidden below the material surface and remain passive. But SACs have to be tested and their performance measured, and until now that has proved a barrier: the process is far too computationally intensive and time consuming to be cost-effective.

That’s where Li’s research comes in. He and his team are using a machine learning approach to achieve exponential improvements in calculating time, raising hopes that SACs could soon become a practical option.

“Algorithms are good at ‘black box’ learning,” Li said. “In this case, the black box is the correlation of atoms to their catalytical performance. We don’t know much, but we do have a few data points resulting from prior experiments—say, for example, we tested a certain element, performed a density-functional theory (DFT) calculation, and determined the performance. We can feed that data to the algorithm and it starts to learn.”

The speed which an algorithm trained in this way can predict an atom’s catalytic performance is nothing short of astonishing: more than 130,000 faster than existing methods. And it can all be done on a laptop computer.

Granted, the algorithm’s math isn’t perfect: like a human student, it makes mistakes at it learns. That’s why part of Li’s work involves testing the algorithm’s findings against known results: in effect, giving it a “final exam,” as he puts it. On average, it tends to be 8.5% off; still enough for an A grade. And the relatively small loss of accuracy is compensated for by the massive gains in speed.

“If we use the old, high-performance computational method, it takes 1,445 CPU hours to calculate a single performance measure,” Li said. “With the machine learning algorithm, it only takes 40 seconds—on a laptop! In this way, we’ve been able to predict all the values for fourteen common transition metals. We now have a library that people can use to determine which SACs perform well, and which ones not so well.”

Citation: Lianping Wu, Tian Guo and Teng Li, Rational design of transition metal single-atom electrocatalysts: a simulation-based, machine learning-accelerated study, J. Mater. Chem. A, 2020,8, 19290-19299

https://doi.org/10.1039/D0TA06207C

Published September 30, 2020