News Story

New Research Could Spur Broader Use of 2D Materials

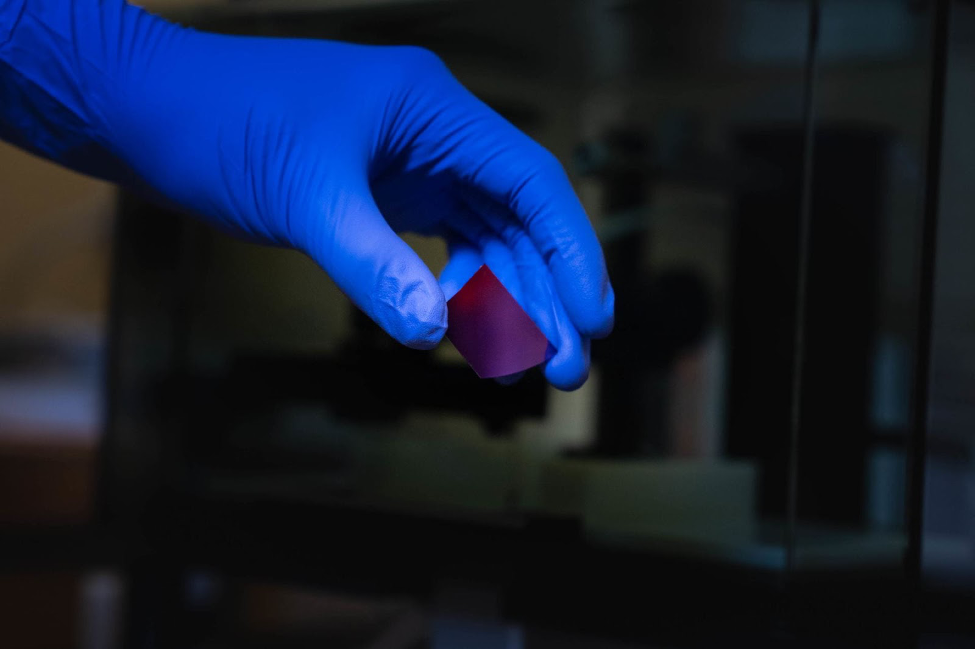

A sample of the covalent organic framework material that researchers found preserves its 2D mechanical properties as a multilayer stack. (Photo by Gustavo Raskosky/Rice University)

They’re considered some of the strongest materials on the planet, but tapping that strength has proved to be a challenge.

2D materials, thinner than the most delicate onion skin paper, have attracted intense interest because of their incredible mechanical properties. Those properties, however, dissipate when the materials are stacked in multiple layers, thus limiting their usefulness.

“Think of a graphite pencil,” says Teng Li, Keystone Professor at the University of Maryland’s (UMD) Department of Mechanical Engineering. “Its core is made of graphite, and graphite is composed of many layers of graphene, which has been found to be the world’s toughest material. Yet a graphite pencil isn’t strong at all—in fact, graphite is even used as a lubricant.”

Now, Li and collaborators at Rice University and the University of Houston have found a way to overcome this barrier, by carefully tweaking the molecular structure of 2D polymers known as covalent organic frameworks (COFs). The findings are detailed in a new study published in Proceedings of the National Academy of Sciences.

“It’s a very exciting starting point,” said Rice University materials science and nanoengineering professor Jun Lou, who led the Rice team.

Using molecular-level simulations, the researchers studied different functional groups—that is, arrangements of molecular elements—and then designed two COFs with minute differences in structure. They then studied how the COFs behaved when stacked into layers. It turned out that the tiny structural differences led to significantly different results.

The first COF, like most 2D materials, showed only a weak interaction among layers, and both strength and elasticity drained away as more layers were added. Not so with the second COF, which “exhibits strong interlayer interaction and retains its good mechanical properties even as multiple layers are added,” said Rice University doctoral student Qiyi Fang, a co-lead author of the PNAS paper.

According to the researchers, this phenomenon is most likely due to hydrogen bonding. “We found from our simulations that the strong interlayer interactions in the second type of COF result from the significantly enhanced hydrogen bonding among its special functional groups,” said co-lead author Zhengqian Pang, a UMD post-doctoral researcher and a member of Li’s research group.

Applying their findings, the research team then produced a lightweight material that not only is several times stronger than steel, but preserves its 2D properties even when stacked into multiple layers.

The potential applications are many. “COFs could make excellent filtration membranes, for instance,” said Rice’s Lou. “For a filtration system, the functional group structure at the pore will be very important. As you have, say, dirty water traveling through a COF membrane, the functional group at the pore will capture the impurities only and allow the desired molecule to pass. In this process, the mechanical integrity of that membrane will be very important. Now we have a way to design very strong, very fracture-resistant, multilayer 2D polymers that could be very good candidates for membrane filtration applications.”

“Another potential application is for upgrading batteries: Replacing the graphite anode with a silicon one would greatly increase the storage capacity of current lithium-ion battery technologies,” he said.

Insights from the research could also lead to advances in designing a broad range of materials, including ceramics and metals, said Li. Ceramics, for instance, depend on ionic bonding that forms at very high temperatures, which is why a broken coffee mug can’t be easily fixed. Metals, likewise, require forging at high temperatures. With the molecular tweaking being explored by the researchers, similar products could conceivably be manufactured and repaired without the turning up heat.

“Although the immediate context is 2D materials, more generally we’re pioneering ways to exploit the advantageous properties of materials without the constraints these materials present,” Li said.

The Army Research Laboratory Cooperative Agreement (W911NF-18-2-0062), the Welch Foundation (C-1716) and the Maryland Advanced Research Computing Center supported the research.

Paper citation:

Superior mechanical properties of multi-layer covalent-organic-frameworks enabled by rationally tuning molecular interlayer interaction | Proceedings of the National Academy of Sciences | DOI: 10.1073/pnas.2208676120

Authors: Qiyi Fang, Zhengqian Pang, Qing Ai, Yifeng Liu, Tianshu Zhai, Doug Steinbach, Guanhui Gao, Yifan Zhu, Teng Li and Jun Lou

https://doi.org/10.1073/pnas.2208676120

Published April 3, 2023