News Story

Clark School Engineers Create Solutions for a Crisis

Firefighters Oscar Montalvo ’10, right, and Tyler Maccrone, hand at left, open a box of “Terpsanitizer,” hand sanitizer created by professors and students in the Department of Chemical and Biomolecular Engineering and donated to the Gaithersburg-Washington Grove Volunteer Fire Department. (Photos by Stephanie S. Cordle)

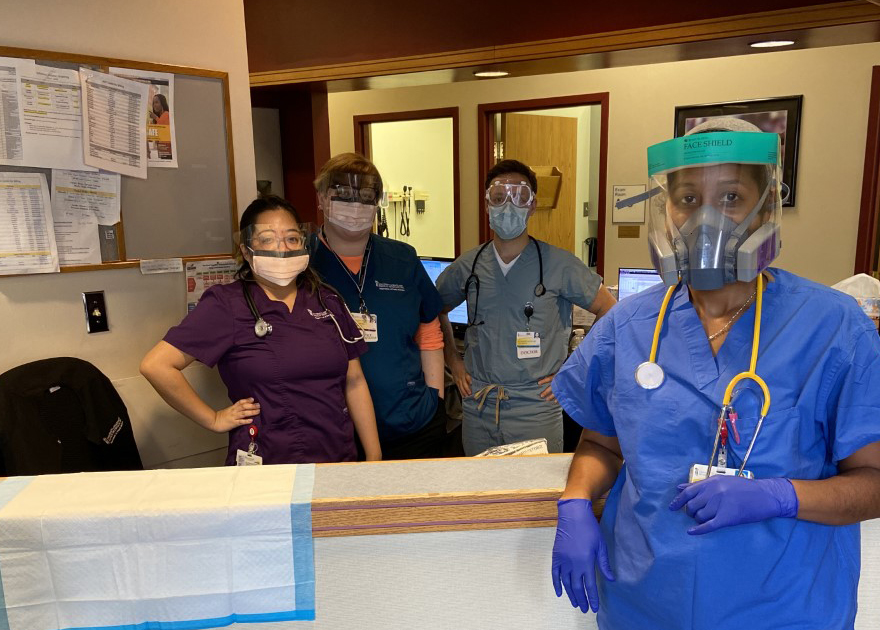

Clark School engineering faculty and students who faced the shuttering of their campus labs to prevent the spread of COVID-19 are now repurposing them to meet the urgent needs of first responders and medical professionals fighting the virus on the front lines.

Associate Professor Dongxia Liu and Assistant Professor Chen Zhang from the Department of Chemical and Biomolecular Engineering have shifted their facilities and equipment to the production of hand sanitizer, while Professor and department Chair Peter Kofinas is using his own to manufacture surgical masks for doctors at Children’s National Hospital in Washington, D.C.

“There’s need for a lot of these products,” said Kofinas. “Hand sanitizers are (sold) out on shelves, so there’s need, and it’s very easy to make.”

Using a recipe from the Food and Drug Administration website, Liu and Zhang, along with graduate students Lu Liu and Zixiao Liu, are creating “Terpsanitizer” out of isopropyl alcohol and aloe vera gel for free distribution. “Isopropyl alcohol is the active ingredient to kill the germs, and the gel reduces skin dryness and irritation,” said Zhang. A small amount of essential oil provides a fragrance. Though the product is not officially FDA-approved, it follows the agency’s guidelines.

On March 25, Kofinas delivered 100 bottles of the product to firefighters with the Gaithersburg-Washington Grove Volunteer Fire Department. As production of the sanitizer continues—aided by a $10,000 commitment by longtime Clark School partner Northrop Grumman to support production costs—Liu, Zhang, and Kofinas also plan to donate it to other first responders and community members, as well as to essential UMD staff and any students remaining on campus.

“A lot of us hadn’t found any hand sanitizer for ourselves—we’re also on the ambulances and possibly exposed to this stuff,” said firefighter Oscar Montalvo ’10, who met Kofinas while training at 2nd Gear Brazilian Jiu Jitsu in Laurel.

Kofinas is also leading a charge on the fabrication of surgical masks. He works with polymers, which can be spun into fibers, and his lab, which collaborates with Dr. Anthony Sandler, surgeon-in-chief at Children’s National Hospital, has adapted this technology to make surgical masks.

“It just takes a few minutes” to make the masks, said Kofinas. In a process he has already used to create an adhesive for surgery, a spray polymer forms fiber masks. They’ve devised several prototypes and plan to soon begin supplying them for use at the hospital. “We hope we can ramp it up,” said Kofinas.

This story originally appeared on Maryland Today.

Are you interested in contributing to the Department of Chemical and Biomolecular Engineering's work in response to COVID-19? Make a gift online.

Published March 25, 2020