Press Release

Could Nanocellulose Save Us?

The building blocks of plants may taper our dependency on fossil fuels.

FOR IMMEDIATE RELEASE February 3, 2021

CONTACT:

Katie Doyle

301 405 0379

khollan3@umd.edu

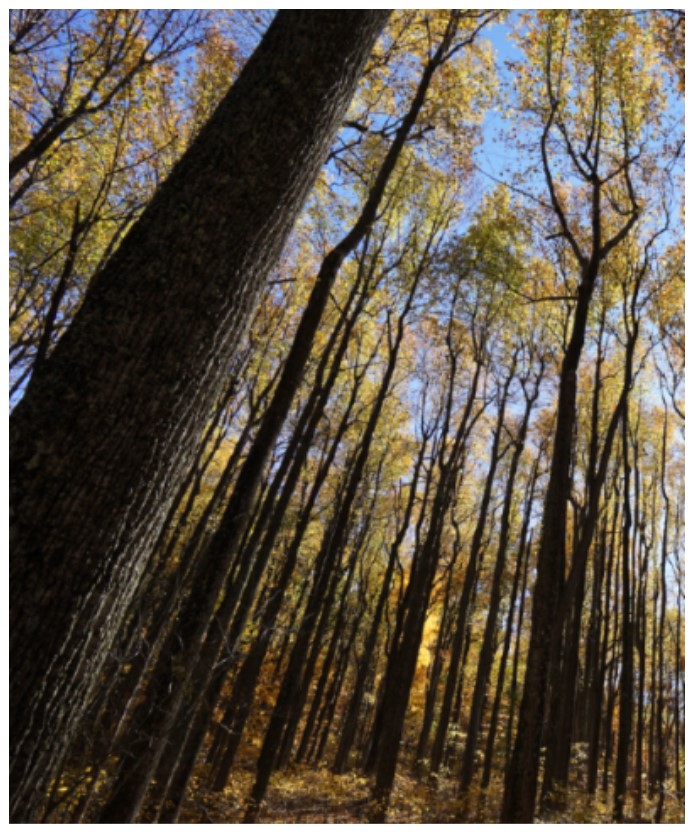

Credit: Dr. Hua Xie for University of Maryland, College Park.

Nanocellulose lines the cell walls of plants, trees, algae and bacteria consisting of glucose rings that link together like a chain and give it a rigged structure. In a perspective published in Nature, a University of Maryland (UMD) research team led by Liangbing Hu - a professor in the Department of Materials Science and Engineering (MSE) and Center for Materials Innovation (CMI) Director - offers a perspective of using nanocellulose as a sustainable technological material towards addressing global challenges. Tian Li and Chaoji Chen, both MSE and CMI Scientists, served as first authors on the paper.

Cellulose fibers can be separated into individual fibrils that look like strands of hair, ranging in diameter from less than 100 μm to roughly nanometer scale. Such fibrillated cellulose is not only eco-friendly, but tunable and cost-effective making its commercialization attractive to manufacturers and consumers alike. As the most abundant organic polymer on Earth, it can enable a vast array of mechanical, optical, thermal, fluidic and ionic applications and explores the possibility of its use as bioplastics, thin films, porous membranes and soft gels. Industry challenges and promises have also been discussed.

According to the study, "With improved fundamental understanding and control of its hierarchical structure, we anticipate that fibrillated cellulose could form the foundation of economically viable, sustainable solutions towards a range of near-term applications in high-performance structural materials and biodegradable technologies, as well as far-term applications in optoelectronics, bio-engineering and membrane science."

Ongoing challenges include sustainability, the balance between biodegradability and product durability, fire safety and public health concerns, although these challenges can be addressed through additional material design and structural engineering. Scalable manufacturing of cellulose, however, shouldn't be an issue given that roughly three trillion trees and plants, such as fast-growing bamboo and sugarcane, are produced daily. Indeed, fibrillated cellulose can provide a practically unlimited resource for innovative new materials.

For additional information: Li, T., Chen, C., Hu, L., et al (2021 Feb. 03). Developing fibrillated cellulose as a sustainable technological material, Nature, DOI: 10.1038/s41586-020-03167-7

About the A. James Clark School of Engineering

The University of Maryland’s A. James Clark School of Engineering is a premier program, ranked among the top 20 in the world. Located just a few miles from Washington, D.C., the Clark School is at the center of a constellation of high-tech companies and federal laboratories, offering students and faculty access to unique professional opportunities.

Our broad spectrum of academic programs, including the world’s only accredited undergraduate fire protection engineering program, is complemented by a vibrant entrepreneurial ecosystem, early hands-on educational experiences, and participation in national and international competitions.

The Clark School is leading research advancements in aerospace, bioengineering, robotics, nanotechnology, disaster resilience, energy and sustainability, and cybersecurity. From the universal product code to satellite radio, SMS text messaging to the implantable insulin pump, our students, faculty, and alumni are engineering life-changing innovations for millions. Learn more at www.eng.umd.edu.