News Story

An Insider’s Look at UMD’s Research on Eco-Friendly HVAC&R

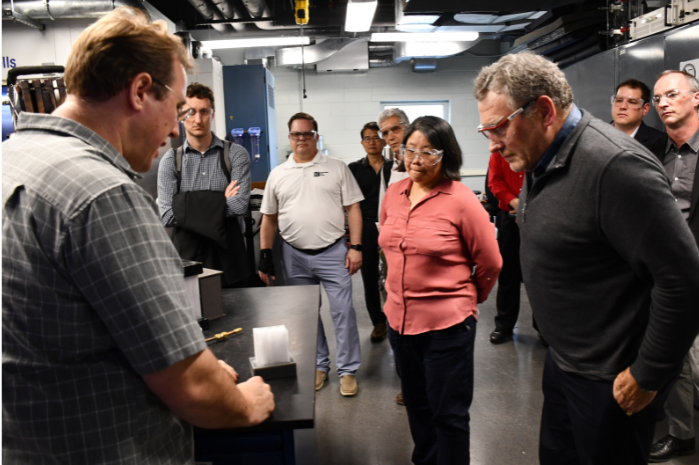

The Daikin Energy Innovation Laboratory is among the labs that will be toured.

Attendees of the 16th IIR-Gustav Lorentzen Conference on Natural Refrigerants, August 11-14 in College Park, Md., are invited to visit the University of Maryland’s state-of-the-art engineering labs, where researchers are developing the next generation of eco-friendly heating, ventilation, air conditioning and refrigeration (HVAC&R) technologies to help slow climate change. Online registration for the conference and the lab tour closes August 2. Already registered for the conference? Update your registration to add the tour.

The lab tour will be held on Wednesday, August 14, 1–2:30 p.m., following the conference's closing ceremony. Tour participants will visit four laboratory areas at the A. James Clark School of Engineering at the University of Maryland:

Daikin Energy Innovation Laboratory. The Daikin Energy Innovation Laboratory is a 3,600 square foot state-of-the-art facility that features the latest equipment for energy engineering, including flame resistant climate chambers, heat transfer measurement technologies and facilities for experimental alternative cooling technologies. See where our researchers are developing elastocaloric cooling devices that offer a solid-state alternative to vapor-compression technology by using shape memory alloys as refrigerants. The lab is run by the university’s Center for Environmental Energy Engineering (CEEE).

George E. Dieter, Jr. Materials Instructional Lab. At the Dieter Lab, tour attendees will learn more about the University of Maryland’s research on elastocaloric cooling, a revolutionary technology that has been shown to offer efficient cooling, with zero direct global warming potential. At the Dieter lab, researchers test the materials and components of the elastocaloric prototype devices developed in the Daikin Energy Innovation Laboratory. In addition to sample preparation (for microscopy, calorimetry, etc.), our engineers conduct a range of mechanical tests such as tension, compression, bending, torsion, fatigue, hardness and impact, using specialized instrumentation. The work is a collaboration between CEEE and the Department of Materials Science and Engineering.

Small and Smart Thermal Systems Laboratory. The Small and Smart Thermal Systems (S2TS) Laboratory focuses on pioneering applications in energy conversion, heat/mass exchangers, process intensification, electronics cooling, and innovative component design and manufacturing for energy systems. The research encompasses state-of-the-art manufacturing techniques, including additive manufacturing and the application of micro and nano-systems for process intensification and optimization. S2TS is also at the forefront of decarbonization efforts, conducting comprehensive and virtual energy audits, energy profiling and energy modeling. The lab is dedicated to developing advanced energy auditing software with machine learning capabilities for precise and efficient energy and carbon assessments and compliance projections. S2TS is home to CEEE’s Advanced Heat Exchangers and Process Intensification industrial consortium, and is affiliated with the Center for Advanced Life Cycle Engineering.

Department of Fire Protection Engineering Laboratories. The University of Maryland offers one of only three graduate fire protection engineering programs in the United States. The department’s laboratories support a broad range of experimental research and teaching, including research related to the safety of alternative natural refrigerants, many of which are flammable or mildly flammable. The large burn room allows flammable refrigerant fires of up to 1 MW. Refrigerant flammability and ignitability are tested in our ASTM E 681 facility and in our windowed vessels of up to 125 L.

For more information about the 16th IIR-Gustav Lorentzen Conference on Natural Refrigerants or to register, click here.

Published July 12, 2024